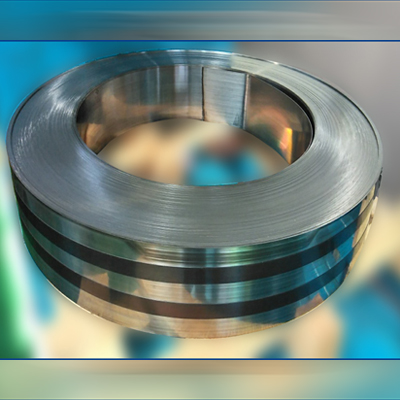

Gang Saw Strip in coil

INTRODUCTION:

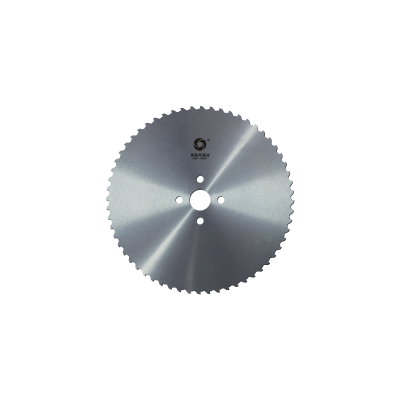

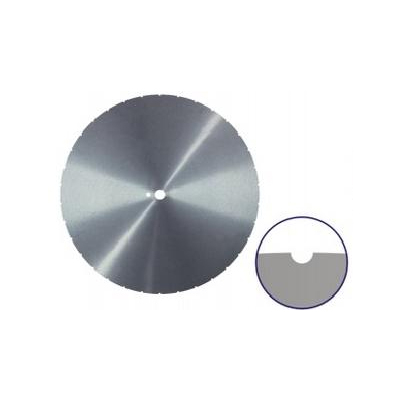

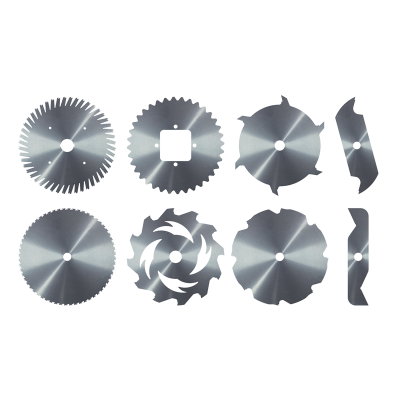

The design principle and applied technology of this processing line adopts advanced technical industry standard and achieves seamless connection with the world advanced technology. Through the accurate control on smelting procedure, hot-rolling billet, cold-rolling smelting procedure (especially control on nodularity and nodulizing grade of the final delivery state), and then through classified hardening and subsequent rehardening craftwork of this processing line. thus, we can produce high grade material for TCT saw blanks. This core competitiveness arising from the model" large-scale state-owned plant+special cold-rolling plant + HXF hardening" facilitates the progress of the technology and industrial upgrading which can substitute imported material.

Comparing with the traditional materials,the mechanical property of this material is greatly improved (increasing tensile strength. longer fatigue life. Improving elongation of section). The processing materials are with high quality, reliable usage, high technology, which will achieve a bright market prospect.

This processing line possess high automation, steady and reliable operation. It can continuously supply more competitive & advanced raw material for saw blanks.

After pretreatment, marquenching and tempering, the performance of steel stripe can reach up to international advanced level.

| 锯片基体专用带钢SPECIAL STEEL FOR SAW BLANKS | |||||||||

| 规格Size | 厚度Thick | 硬度 HRC | 材质 MATERIAL | ||||||

| φ100-φ650 | 1.0~4.5 | 根据客户要求定制 CUSTOMIZED | 75CR1、80CRV2、SKS51等 | ||||||

| 材料形状 Material shape | 板料 Sheet | 卷料 Coil | 圆板 Round disc |

| 长度/外径/卷径 Length/outside diameter/ Roll diameter | ≦4000mm | ≦Φ1800 | |

| 宽度 (公差Tolerance | ≦540 | ≦185 | ≦Φ535 |

| 厚度 (公差Tolerance | 1.2≦h≦4.0mm | ||

| 材质 Material | 75Cr1/SKS51 | ||

| 硬度 (公差Tolerance | HRC35-51 | ||

| 平面度 Flatness | ≦宽度 Width×1‰ | ≦宽度 Width×1‰ | 0.05mm |

INTRODUCTION:

The design principle and applied technology of this processing line adopts advanced technical industry standard and achieves seamless connection with the world advanced technology. Through the accurate control on smelting procedure, hot-rolling billet, cold-rolling smelting procedure (especially control on nodularity and nodulizing grade of the final delivery state), and then through classified hardening and subsequent rehardening craftwork of this processing line. thus, we can produce high grade material for TCT saw blanks. This core competitiveness arising from the model" large-scale state-owned plant+special cold-rolling plant + HXF hardening" facilitates the progress of the technology and industrial upgrading which can substitute imported material.

Comparing with the traditional materials,the mechanical property of this material is greatly improved (increasing tensile strength. longer fatigue life. Improving elongation of section). The processing materials are with high quality, reliable usage, high technology, which will achieve a bright market prospect.

This processing line possess high automation, steady and reliable operation. It can continuously supply more competitive & advanced raw material for saw blanks.

After pretreatment, marquenching and tempering, the performance of steel stripe can reach up to international advanced level.