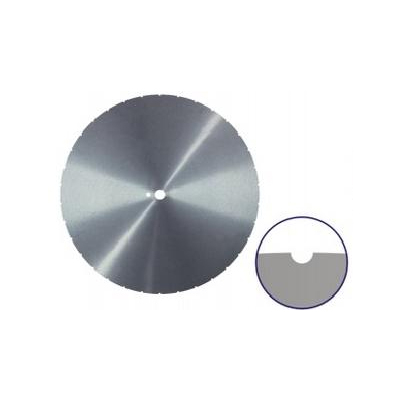

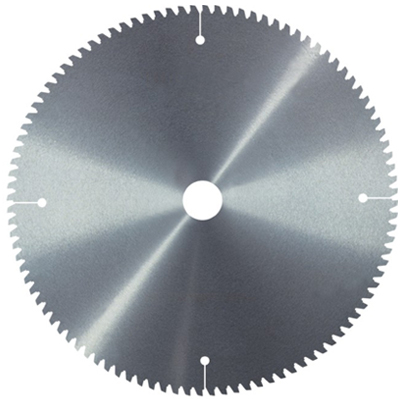

Glue-filled Silent Saw Blanks

Suitable for Φ200-Φ2200mm diamond saw blanks , mainly applicable for cutting fields of stone, glass, concrete, semiconductor, non-ferrous metal profile, ferrous metal profile, wood, graphite and so on.

1,Fine denoising performance, similar denoising effect comparing with sandwich silent saw blanks.

2,The integral saw blank is made of one single steel sheet,comparing with sandwich silent saw blanks, it efficiently increases the welding intensity, and its rigidity is much better than sandwich silent saw blank's.

3,Adopting special key craft and unique design of laser cutting kerf, ensuring the reliable bond strength of glue and laser-cutting kerf, also ensuring the rigidity of the saw blanks, the saw bodies can be normally processed by grinding and flatting.

200mm-2200mm full range of specifications customized

1. Technical Definition and Process Principle

The glue filling technology is an advanced noise reduction solution that achieves vibration damping by precisely hollowing out the saw blanks and injecting elastic material. Its core principle is to suppress resonance through the conversion of mechanical energy into thermal energy.

Professional Application Scenarios

(1) Urban Noise Reduction Projects

• Nighttime subway construction (compliant with GB12523-2022 Class III)

• Cutting operations near hospitals/schools

• High-end residential renovation projects

(2) Precision Machining Applications

• Marble mosaic art cutting

• Super thin stone slab (3mm) precision cutting

• Tombstone relief carving

(3) Special Environment Operations

• Ship interior maintenance

• Metal cutting in explosion-proof zones

• High-altitude work platform construction

Six Core Advantages

Value Chain Enhancement Analysis:

1. Noise Reduction Compliance: Easily meets the 85dB urban construction standard

2. Cutting Stability: Reduces dimensional deviation rate by 30%

3. Operational Comfort: Extended continuous operation time to over 8 hours

4. Equipment Protection: Main spindle bearing lifespan increased by 2-3 times

5. Material Savings: Reduced cutting waste by 5-8%

6. Environmental Benefits: Reduced costs for soundproofing facilities