Step Silent Saw Blanks for Decton-Cutting

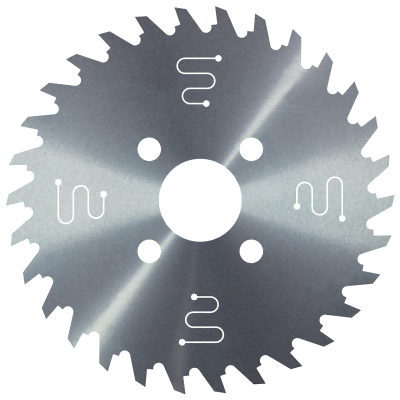

Silent Step saw blanks for Decton cutting

Our silent step saw blanks for Dekton-cutting adopts a sandwich structure, consisting of two layers of steel of equal or unequal thickness and a layer of copper. The multi layers are jointed together by welding or glueing, which achieves a good denoiseing performance.

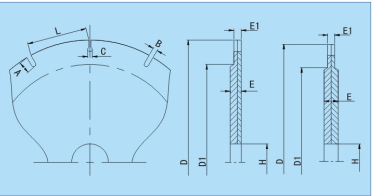

Through processing step on the outer circle, which are divided into single-sided step and double-sided step, The bodies’ outer thickness are reduced and the rigidity of bodies hub are reinforced. It can meet the needs of customers to thin the blade segments, reduce cutting resistance, make the cutting sharper, make the cutting surface smoother, and save the cost.

Silent Step saw blanks for Decton cutting

Our silent step saw blanks for Dekton-cutting adopts a sandwich structure, consisting of two layers of steel of equal or unequal thickness and a layer of copper. The multi layers are jointed together by welding or glueing, which achieves a good denoiseing performance.

Through processing step on the outer circle, which are divided into single-sided step and double-sided step, The bodies’ outer thickness are reduced and the rigidity of bodies hub are reinforced. It can meet the needs of customers to thin the blade segments, reduce cutting resistance, make the cutting sharper, make the cutting surface smoother, and save the cost.