Multi Saw Blanks

Definition and Basic Description

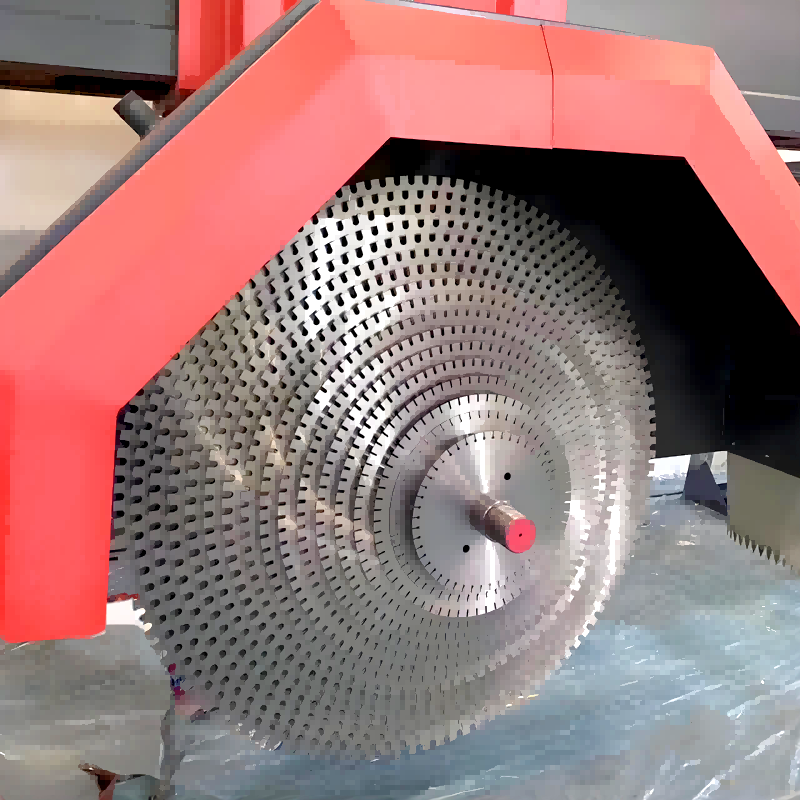

Multi diamond saw for stone is a highly efficient stone processing tool consisting of multiple diamond saw blades installed at specific intervals on the same shaft to form a cutting “saw group.” This design enables multiple parallel cuts to be completed in a single pass, significantly improving processing efficiency.

Core Structural Components:

· Blanks Material: Typically made of high-quality 75Cr1 alloy steel or higher-strength materials

· Blanks Type: Different diamond grit sizes/concentrations can be selected based on the hardness of the stone

· Spacer System: Precision-machined steel spacers ensure accurate spacing between saw blades

· Locking System: High-strength flanges and locking nuts ensure stable operation

· Cooling Channels: Specially designed coolant channels enhance heat dissipation

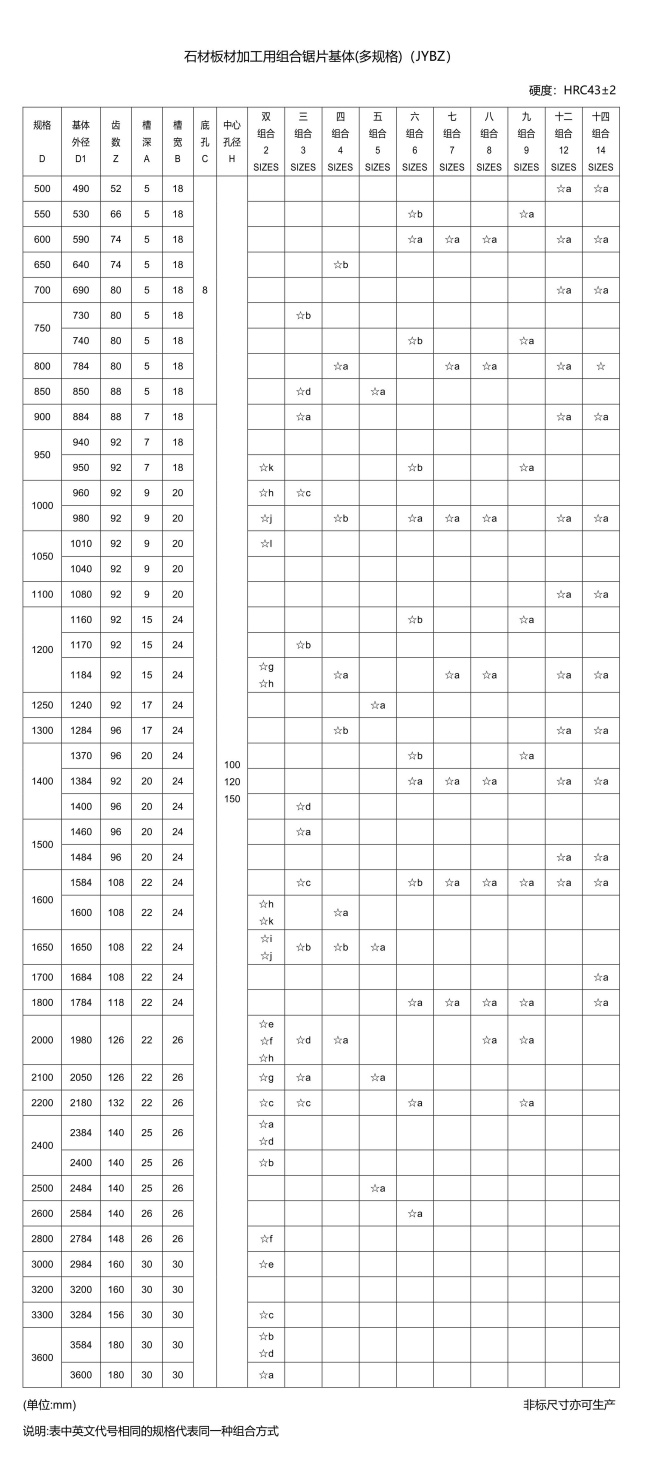

Full-specification customized production with thickness ranging from 2.5 mm to 7.5 mm and diameter ranging from 200 mm to 4500 mm.

1. Definition and Basic Description

Multi diamond saw for stone is a highly efficient stone processing tool consisting of multiple diamond saw blades installed at specific intervals on the same shaft to form a cutting “saw group.” This design enables multiple parallel cuts to be completed in a single pass, significantly improving processing efficiency.

Core Structural Components:

· Blanks Material: Typically made of high-quality 75Cr1 alloy steel or higher-strength materials

· Blade Type: Different diamond grit sizes/concentrations can be selected based on the hardness of the stone

· Spacer System: Precision-machined steel spacers ensure accurate spacing between saw blades

· Locking System: High-strength flanges and locking nuts ensure stable operation

· Cooling Channels: Specially designed coolant channels enhance heat dissipation

Translated with DeepL.com (free version)

2. Main Application Scenarios

(1) Mass Production of Stone Slabs

• Granite slab cutting: Can cut 10–30 standard-thickness (20 mm/30 mm) slabs in a single operation

• Marble slab production line: Efficiently processes entire blocks of raw material

• Quartz stone cast slab cutting: Precisely controls slab thickness

(2) Processing of Special-Specification Stone Blocks

• Curb stone production: Simultaneously cut multiple standard-sized curbstones

• Architectural decorative trim: Form multiple decorative trim pieces in a single operation

(3) Initial Processing of Mine Blocks

• Pre-cut giant blocks into medium-sized pieces suitable for transportation

(4) Special Material Processing

• Cutting of engineered stone composite panels

• Cutting of high-performance concrete precast components

3.Comparison of Core Advantages

| Advantageous dimensions | Traditional single saw blade | Multi-blade combination saw |

Production efficiency | Single cut each time | Synchronous multi-channel cutting, 3-10 times more efficient |

| Processing accuracy | Dependence on operational experience | High dimensional consistency, tolerance ±0.2mm |

| material utilization rate | Significant loss | Optimizing cutting plans can reduce material waste by 15% to 30%. |

| Energy consumption ratio | High energy consumption per unit of output | Comprehensive energy consumptionreduced by approximately 40% |

| labor costs | Requires multiple operators | Automated assembly line production can be achieved. |

4. Detailed Technical Features

(1) Spacing Adjustment System

• Utilizes high-precision spacing sleeves (adjustable from 1-100mm)

• Compatible with micro-adjustment shims (0.1mm-level adjustment)

• Special anti-loosening design to prevent shifting during operation

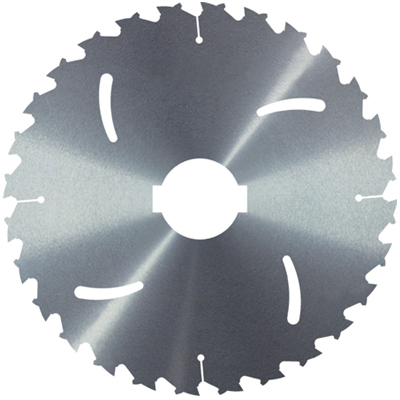

(2) Blade Configuration Options

• Optional mixed configuration (guide saw blade + main cutting saw blade)

• Variable diameter design (reinforced treatment on the first and last blades)

• Different grit combinations (coarse cutting + fine finishing combination)

(3) Cooling System

• Central water injection design

• Independent cooling channels for each blade

• Optional oil mist cooling system (for special operating conditions)